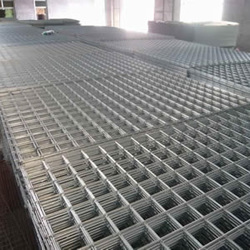

Electro Welded Wire Mesh, produced at the Long Yi facility, is characterized by a high yield stress. The HD (High Ductility) brand distinguishes the wire mesh for the excellent ductility grade assuring maximum safety structural behaviors. It is possible to produce, upon request, customized wire mesh and/or to drawing to meet the specific standards or special calculation requirements. It is a concrete reinforcement element, made of smooth or corrugated wires welded to each other perpendicularly, obtaining perfectly squared grid meshes.

Perimeter finish

Up to five different types of finish, depending on the specific application: with overhangs, flush edges, trimmed with an inclined cut, with single or double wire edging.

Finish

Rough (self color) – galvanized –galvanized Zn+Al – stainless steel – painted (epoxy or polyester) – copper washed.

Technical Info:

Wire diameter for Electro Welded Wire Mesh ranges from 5mm to 16mm.

Electro Welded Wire Mesh opening: 75mm to 300mm.

Panel length: 100cm to 1400cm.

Panel width: 100cm to 300cm.

Features:

Electro Welded Wire Mesh costs less time and labor in work. It saves about 50 to 70 percent work time compared with common binding wire mesh. The use of Electro Welded Wire Mesh can also strengthen the concrete parts to reduce surface breaking ratio. Electro Welded Wire Mesh for reinforcement is especially suitable for big area concrete engineering. Using of Electro Welded Wire Mesh can save about 10 percent of the total cost of the project.

Applications:

Mattress supports

Fan grilles

Benches

Containers

Animal cages

Cable trays

Plaster reinforcement for secondary frames

Overpass fencing

Foundations and plasterwork

Special structural work

Solo net (food industry)

Machine guards

Fencing in general

Perimeter finish

Up to five different types of finish, depending on the specific application: with overhangs, flush edges, trimmed with an inclined cut, with single or double wire edging.

Finish

Rough (self color) – galvanized –galvanized Zn+Al – stainless steel – painted (epoxy or polyester) – copper washed.

Technical Info:

Wire diameter for Electro Welded Wire Mesh ranges from 5mm to 16mm.

Electro Welded Wire Mesh opening: 75mm to 300mm.

Panel length: 100cm to 1400cm.

Panel width: 100cm to 300cm.

Features:

Electro Welded Wire Mesh costs less time and labor in work. It saves about 50 to 70 percent work time compared with common binding wire mesh. The use of Electro Welded Wire Mesh can also strengthen the concrete parts to reduce surface breaking ratio. Electro Welded Wire Mesh for reinforcement is especially suitable for big area concrete engineering. Using of Electro Welded Wire Mesh can save about 10 percent of the total cost of the project.

Applications:

Mattress supports

Fan grilles

Benches

Containers

Animal cages

Cable trays

Plaster reinforcement for secondary frames

Overpass fencing

Foundations and plasterwork

Special structural work

Solo net (food industry)

Machine guards

Fencing in general

RSS Feed

RSS Feed